NG/E&Y potential: 3,098 - 6,668m m3

Credible potential: 0 - 3,700m m3

Of the waste streams listed by NG/E&Y, at least two – wood waste and miscanthus – must have been envisaged as feedstock primarily for gasification, not digestion. As explained above, we should probably add (despite its name) the biodegradable waste, as effectively the paper and card waste stream.

Of approximately 4.5m tonnes of waste wood produced in the UK, around 2.1m tonnes is currently going to biomass energy projects.[1] 1.35m tonnes is reused and 0.3m tonnes is exported.

The total amount of waste wood was not dissimilar in 2009.[2] The majority was from construction and demolition waste, which introduces challenges of identifying and handling the treated wood. WRAP estimated that only around 1.4m tonnes was “clean solid wood”.

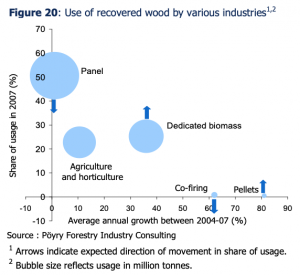

WRAP seem to indicate that almost all of it was already being recovered, driven primarily by the wood panel industry.[3] Nevertheless, WRAP expected recovery to increase overall, and energy-use to increase (driven by the RO, i.e. for electricity generation) while panel manufacturers’ share fell.[4]

Barring the complete implosion of British panelboard manufacturing, it was reasonable for NG/E&Y to assume that a material proportion of the clean waste wood would continue to go to this use. Likewise, animal bedding and other existing forms of re-use.

Around 2m tonnes of waste wood available for energy-use, seems to be a recurring figure from the studies, which would have been a reasonable top-end figure for gasification assuming it displaced all other energy-uses. It is also consistent with what happened in practice under the incentives of the RO and RHI, although of course it went almost entirely to mature combustion technologies and not to gasification.

We set out below what might be credible if the UK made ambitious efforts to produce energy crops for digestion. The constraining figures are the same for gasification feedstocks. The same amount of land is available, and the uses are mutually exclusive.

A key difference is that the technology for digestion is mature. We might therefore prioritise energy-crop land-use for digestion rather than gasification. Nevertheless, not all land is equally suitable for all crops, so there might well be a mix. Some proportion of the figure estimated below for energy crops might have been available for gasification instead of digestion. In practice, 7,000 ha produced around 71,000 odt of miscanthus in 2018.[5]

So we have a maximum potential gasification feedstock of around 5-6 million tonnes of paper and cardboard, 2 million tonnes of waste wood, and perhaps 6 million tonnes of energy crops.[6] That’s around 63 TWh of feedstock (which does not mean 63 TWh of potential biomethane, because of conversion efficiencies, as below). Around 27 TWh of that is mutually exclusive with the upper estimate for digestion energy crops.

The true problem for gasification starts when we consider how this would be used. Gasification technology is in one sense very mature. It has been known and used for decades.[7] But in another sense, it is still immature. Despite many attempts in recent decades to commercialise it, no offering has succeeded to any significant extent.

One problem relevant to this report is the nature of the feedstock. Gasification was only ever deployed at scale for the conversion of coal, which is a homogeneous fuel. Recent efforts have focused on more heterogeneous feedstocks, such as waste. But the process needs very precise control of energy-feed-rate, air, etc. Many gasification projects have foundered on the front-end.

Another major problem for these purposes is that gasification does not produce biomethane. It produces a mixture of methane (CH4), carbon monoxide (CO) and hydrogen (H2), to name the three main combustible elements of the gaseous product. In the days of town gas, this mixture was permitted in the gas network. Nowadays, there is a very tight specification for the gas that can be accepted into the network: largely methane with a small amount of more-complex alkanes. For operational and safety reasons, gasification gas could no longer be added to the gas network. So one immature technology (gasification) would have to be complemented by an even less mature technology (methanation) to convert the gasification gas into a gas that could be distributed to users.

Considerable effort has been invested in recent years in gasification + methanation to produce a Synthetic Natural Gas (SNG). But (a) it is 2020 and none of those are commercially mature, and (b) NG/E&Y could not reasonably have predicted that they would be, given the state of technology and the market in 2009. Decades of efforts around the world had resulted in no commercial options to date. The prudent assumption was that 10 years was not long enough for the problems to be ironed out and the technology commercialised.

Yet NG/E&Y included the following quantities of biogas from gasification in their baseline projection: 1,253m m3 from wood waste, 1,845m m3 from miscanthus, and (probably) 1,042m m3 from biodegradable waste. This constituted 74% of the 5,625m m3 of biogas that they envisaged would be available as a minimum in 2020.

Of all their imprecisions, this is the most egregious. The only reasonable figure to use for this technology in the baseline scenario was zero. Decades of effort had so far delivered almost nothing. And sure enough, from the perspective of 2020, we find that the most recent decade also produced almost no commercial SNG production, not just in the UK, but globally.

As for the “stretch” scenario, how much biogas might those 63 TWh of feedstock have produced? The conversion efficiencies of gasification and methanation are both typically estimated at around 80%, so we will assume the combined efficiency would be 64%. That implies a maximum of around 40 TWh of biomethane from this source.

At 10.83 kWh/m3 of methane, that’s around 3.7bn m3 of biomethane. NG/E&Y had 2,697m m3 from wood waste, 3,971m m3 from miscanthus, and 8,328m m3 from biodegradable waste (probably). This technology now accounted for 81% of the total 18,432m m3 of biomethane anticipated in the “stretch” scenario.

In other words, gasification and these feedstocks, were NG/E&Y’s deus ex machina to convert what was obviously an inadequate potential of digester gas, to an apparently-significant potential of biomethane. Unfortunately, it was not just a misestimation; it was a fiction with no basis for reasonable expectation given the knowledge available at the time.

[2] WRAP, Wood waste market in the UK (2009), https://www.wrap.org.uk/sites/files/wrap/Wood%20waste%20market%20in%20t…

[3] “In 2007, just over half of wood waste was used by panel manufacturers. Dedicated biomass energy generators used a quarter; agricultural or horticulture product manufacturers used a fifth; and pellet producers and co-firing energy generators the remainder.” Although this refers to wood waste as a whole, one suspects they were referring to shares of the proportion that was recovered.

[4] One way to make sense of the figures is that WRAP’s figures referred to the recovered quantities of waste wood, although that seems to conflict with the fact that the majority of their 4.5m tonnes was hard-to-recover construction and demolition waste. But perhaps the relatively-low figures for those components reflected the fact that they were the recoverable element. In an earlier analysis, WRAP had put the figure significantly higher at around 10.6m tonnes of waste wood in total (DEFRA, Waste Wood as a Biomass Fuel, 2008, https://www.forestresearch.gov.uk/documents/2078/DEFRA_Waste_wood_as_a_biomass_fuel_2008.pdf). WRAP’s 2009 report also noted that volumes were in decline because of the Crash and its impact on panelboard manufacturers and others, and that their tonnages for construction and demolition waste might be incomplete. But they also noted that theirs was a more detailed study. The true figure is presumably somewhere between 4.5m and 10.5m tonnes. Despite the higher total, the 2008 report nevertheless envisaged an ambition of around 2m tonnes for energy-use.

[6] 6m tonnes of energy crops is calculated on the basis that 2.5bn m3 of biogas is around 27 TWh, which is around 6m tonnes of low-moisture wood (at 4.5MWh/tonne).

[7] Coal gasification was the source of the town gas used in the UK before natural gas displaced it during the 60s. It was an essential part of the technology used by the Germans during the War to convert their plentiful reserves of coal to compensate for their inadequate supplies of petroleum.